Defects: Causes and Fixes

Laser welding stainless steel offers unmatched precision, but defects can still occur when material preparation, process parameters, or shielding gas delivery are not fully optimized. Unlike arc welding, laser welding’s small molten pool solidifies extremely quickly, so even minor disruptions in energy delivery or shielding can produce visible or hidden flaws. Below is a detailed breakdown of common defect types, their root causes, and proven corrective actions.

Porosity

· Metallurgical Cause: Gas bubbles (hydrogen, oxygen, nitrogen) trapped in the molten pool during solidification. Hydrogen is the most common culprit—often from moisture or hydrocarbons on the joint surface.

· Laser-Specific Triggers:

1. Inadequate degreasing (cutting fluids, oils, adhesive residue).

2. Moisture absorption from humid environments.

3. Shielding gas turbulence draws in ambient air.

· Fixes:

1. Cleanliness: Solvent-clean and dry parts immediately before welding.

2. Shielding: Maintain laminar gas flow; use larger nozzles or diffusers to prevent turbulence.

3. Parameter Adjustment: Slightly reduce travel speed to allow gases to escape before solidification; avoid excessive keyhole depth that can trap gases.

Hot Cracking (Solidification Cracking)

· Metallurgical Cause: Low ferrite content in fully austenitic welds leaves impurities concentrated at grain boundaries during solidification. Tensile stresses from shrinkage trigger cracks before full solidification.

· Laser-Specific Triggers:

1. Very high travel speeds produce narrow, fully austenitic solidification.

2. Rigid fixturing that restricts contraction.

· Fixes:

1. Metallurgical: Use filler with higher ferrite potential (e.g., ER308L, ER316L) to target 3–8% ferrite.

2. Stress Management: Reduce restraint in fixturing; stagger welds to spread shrinkage forces.

3. Parameter Tuning: Avoid ultra-high speeds in sensitive grades; adjust beam focus for slightly wider bead profile.

Lack of Fusion / Incomplete Penetration

· Metallurgical Cause: Incomplete melting of joint faces or root due to insufficient energy density or poor beam positioning.

· Laser-Specific Triggers:

1. Defocused beam from incorrect focal position.

2. Misalignment between the beam and the joint centerline.

3. Excessive travel speed.

· Fixes:

1. Optics: Verify focal length and position; check for lens contamination.

2. Parameters: Increase power or reduce travel speed; reduce wobble amplitude if excessive.

3. Fit-Up: Improve joint preparation and ensure gap <0.1 mm for autogenous welds.

Undercut / Underfill

· Metallurgical Cause: Base metal melting away at the weld toe without sufficient molten metal filling it.

· Laser-Specific Triggers:

1. High energy density combined with fast travel, which washes away the toe metal.

2. Off-center beam placement.

· Fixes:

1. Reduce travel speed or beam offset to improve wetting.

2. Add filler wire for gap bridging or bead shaping.

3. Adjust the shielding gas to avoid an excessive plasma plume that destabilizes the molten pool.

Keyhole Instability / Spatter

· Metallurgical Cause: Fluctuations in the vapor cavity (keyhole) lead to collapse or ejection of molten metal.

· Laser-Specific Triggers:

1. Excessive power density causes violent vaporization.

2. Contamination creates uneven absorption.

3. Poor shielding gas choice or flow causing unstable plume.

· Fixes:

1. Lower peak power density slightly; adjust focal position for stability.

2. Ensure surfaces are oxide-free and dry.

3. Use helium blends to stabilize the keyhole in deep penetration mode.

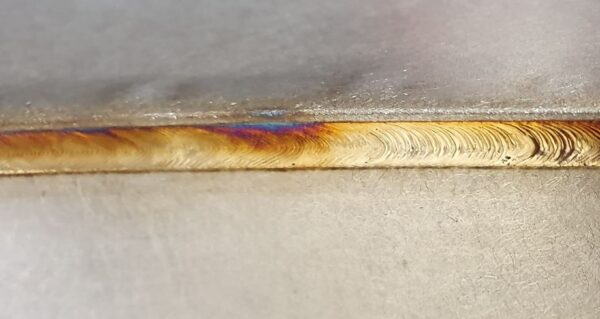

Discoloration and Oxidation

· Metallurgical Cause: Chromium in stainless steel oxidizes when hot metal is exposed to oxygen, forming a heat tint that can reduce corrosion resistance.

· Laser-Specific Triggers:

1. Insufficient shielding gas coverage during and after welding.

2. Too high interpass or cooling temperatures without trailing protection.

· Fixes:

1. Increase primary shielding and add trailing shields to cover the cooling bead for 2–5 seconds.

2. Use high-purity gas (>99.99%).

3. Minimize heat input while maintaining penetration.

Excessive Distortion

· Metallurgical Cause: Stainless steel’s high coefficient of thermal expansion magnifies even small temperature changes, producing shrinkage stresses.

· Laser-Specific Triggers:

1. Overpowered beam for the joint thickness.

2. Long, continuous welds without a balanced sequence.

· Fixes:

1. Reduce heat input via speed or power adjustments.

2. Sequence welds to balance stresses.

3. Use fixtures with controlled clamping that allow limited expansion without losing alignment.

In stainless steel laser welding, most defects stem from one of four root causes: contamination, poor beam control, incorrect heat input, or inadequate shielding. Porosity comes from contamination or gas entrapment, hot cracking from poor ferrite control and high restraint, lack of fusion from insufficient penetration, undercut from poor beam alignment, keyhole instability from unstable vapor cavities, discoloration from oxygen exposure, and distortion from thermal imbalance. The fix is always targeted: remove the root cause, not just the symptom, by addressing preparation, parameters, and shielding gas delivery.

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us