Summary

Laser welding has become a leading method for joining stainless steel thanks to its precision, low heat input, and suitability for automation. When set up correctly, it delivers deep penetration, minimal distortion, and clean welds that preserve stainless steel’s corrosion resistance. Successful results depend on more than just laser power—material preparation, joint design, shielding gas strategy, and parameter control are equally critical.

Understanding stainless steel families helps match welding techniques and filler metals to metallurgical needs, whether controlling ferrite in austenitics or balancing phases in duplex grades. Proper surface preparation eliminates contaminants that cause porosity or oxidation, while good fixturing, tack welding, and path planning keep parts in alignment. Controlling heat input and cooling rate ensures optimal microstructure, and choosing the right shielding gas prevents discoloration and preserves corrosion performance.

By recognizing common defects—such as hot cracking, lack of fusion, or keyhole instability—and applying targeted fixes, fabricators can maintain both weld quality and productivity.

Ultimately, laser welding stainless steel is about controlling every variable in the process. From preparation through final inspection, attention to detail ensures welds that meet structural demands, aesthetic expectations, and the long-term durability stainless steel is known for.

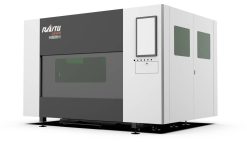

Get Laser Welding Solutions

Choosing the right equipment and process setup is critical to unlocking the full potential of stainless steel laser welding. From selecting the optimal laser source to fine-tuning beam delivery, shielding, and automation, every decision affects weld quality, productivity, and long-term reliability. That’s where working with an experienced technology partner makes the difference.

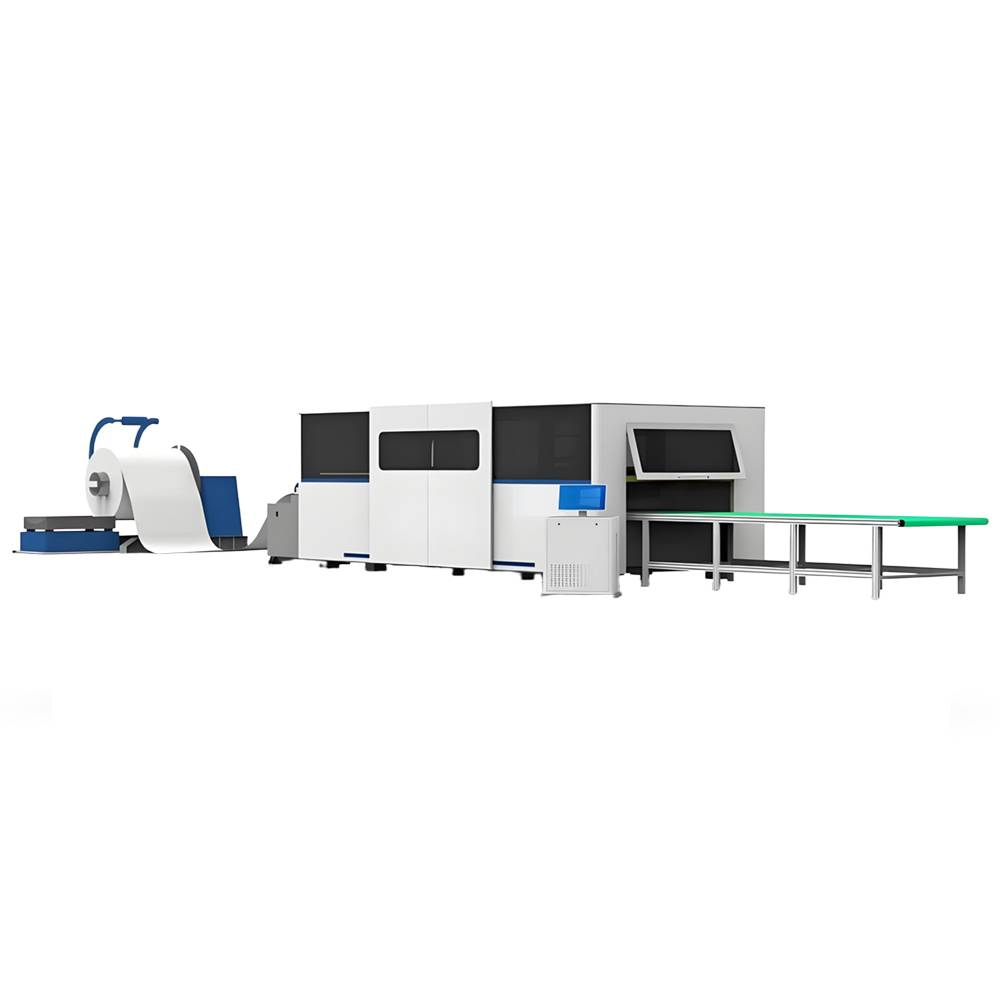

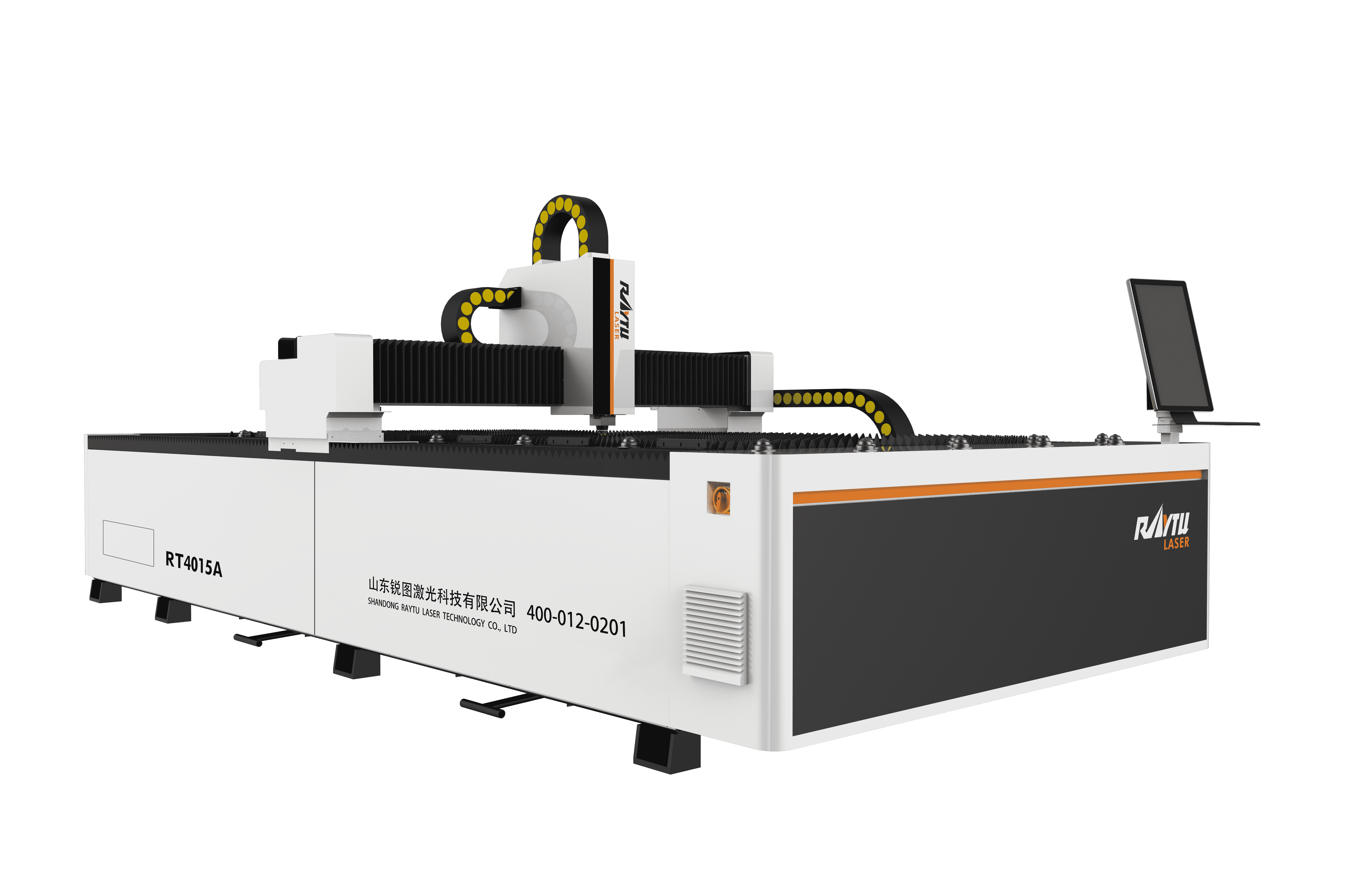

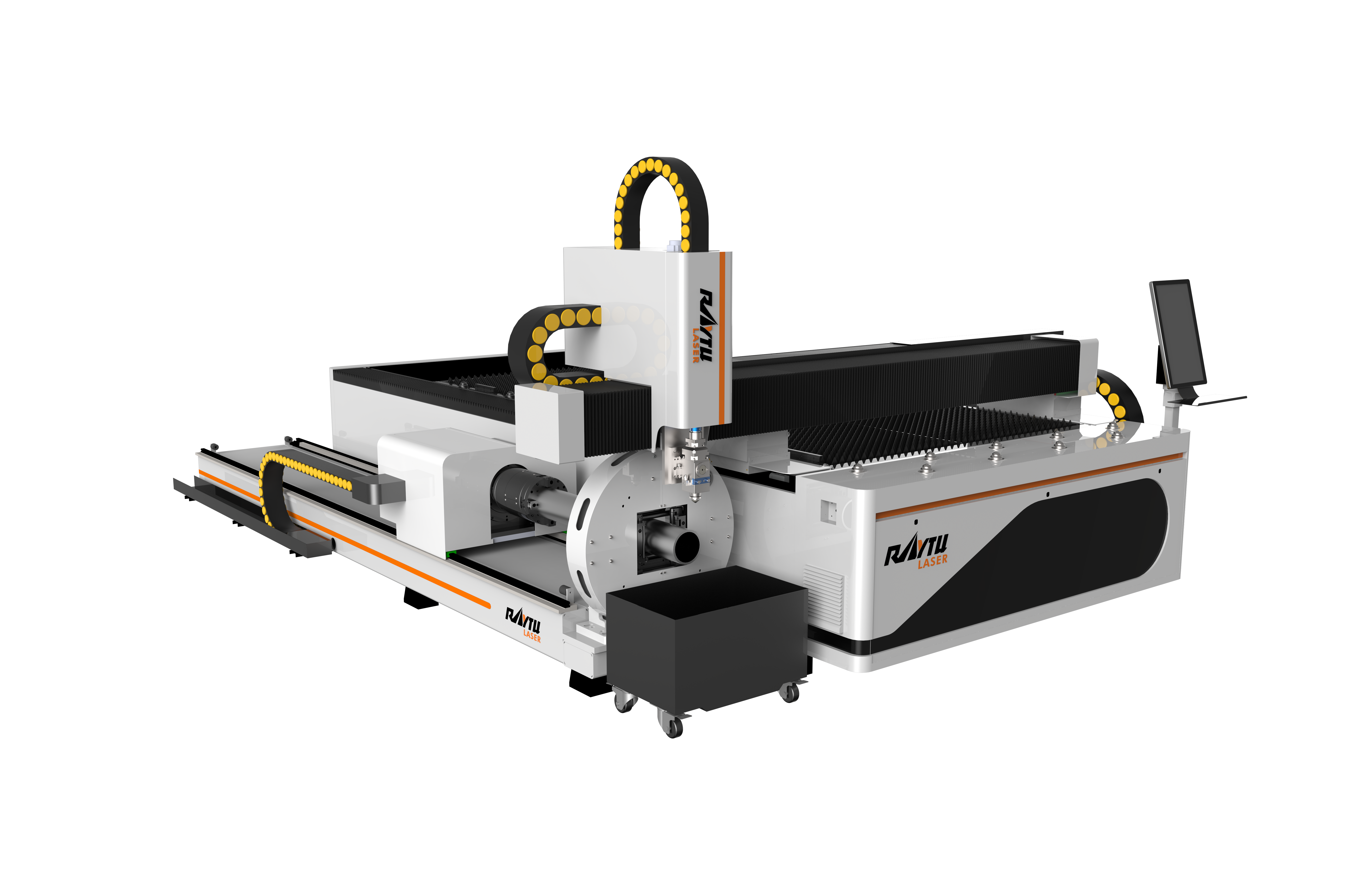

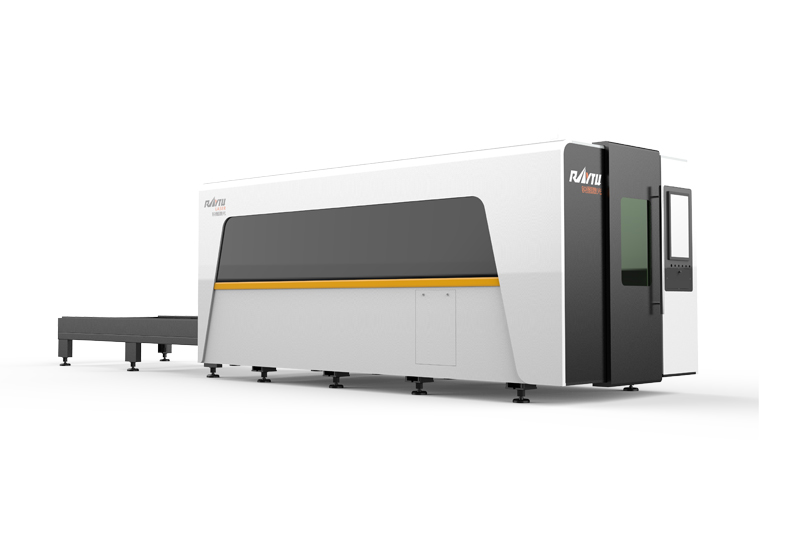

Raytu Laser is a professional manufacturer of intelligent laser equipment, providing tailored solutions for stainless steel welding in industries ranging from precision fabrication to heavy manufacturing. Our portfolio includes high-efficiency laser welding machines, advanced wobble heads for improved gap tolerance, automated motion systems, and integrated shielding solutions to protect weld integrity.

Beyond equipment, we offer process support—helping you match parameters, joint designs, and shielding strategies to your specific stainless steel grade and application. Whether you need deep-penetration welds for structural components or cosmetic seams for food-grade products, our engineering team can configure a system that meets both technical requirements and production targets.

With Raytu Laser, you don’t just buy a machine—you gain a partner committed to delivering consistent, high-quality welds and helping you stay ahead in a competitive market.

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us