Tube Laser Cutting Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

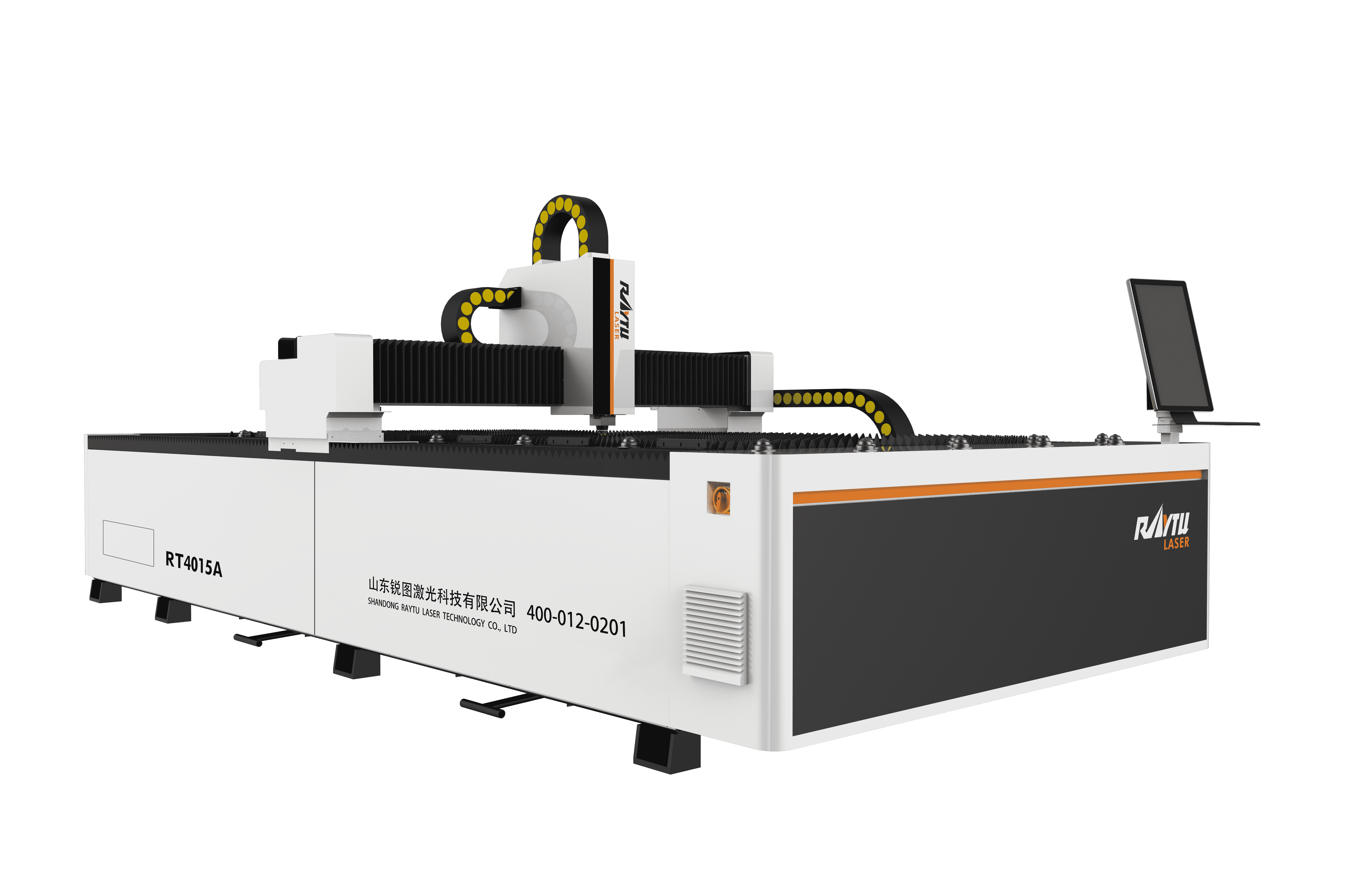

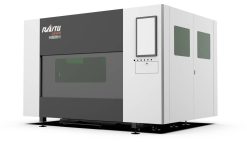

Sheet Metal Laser Cutting Machine

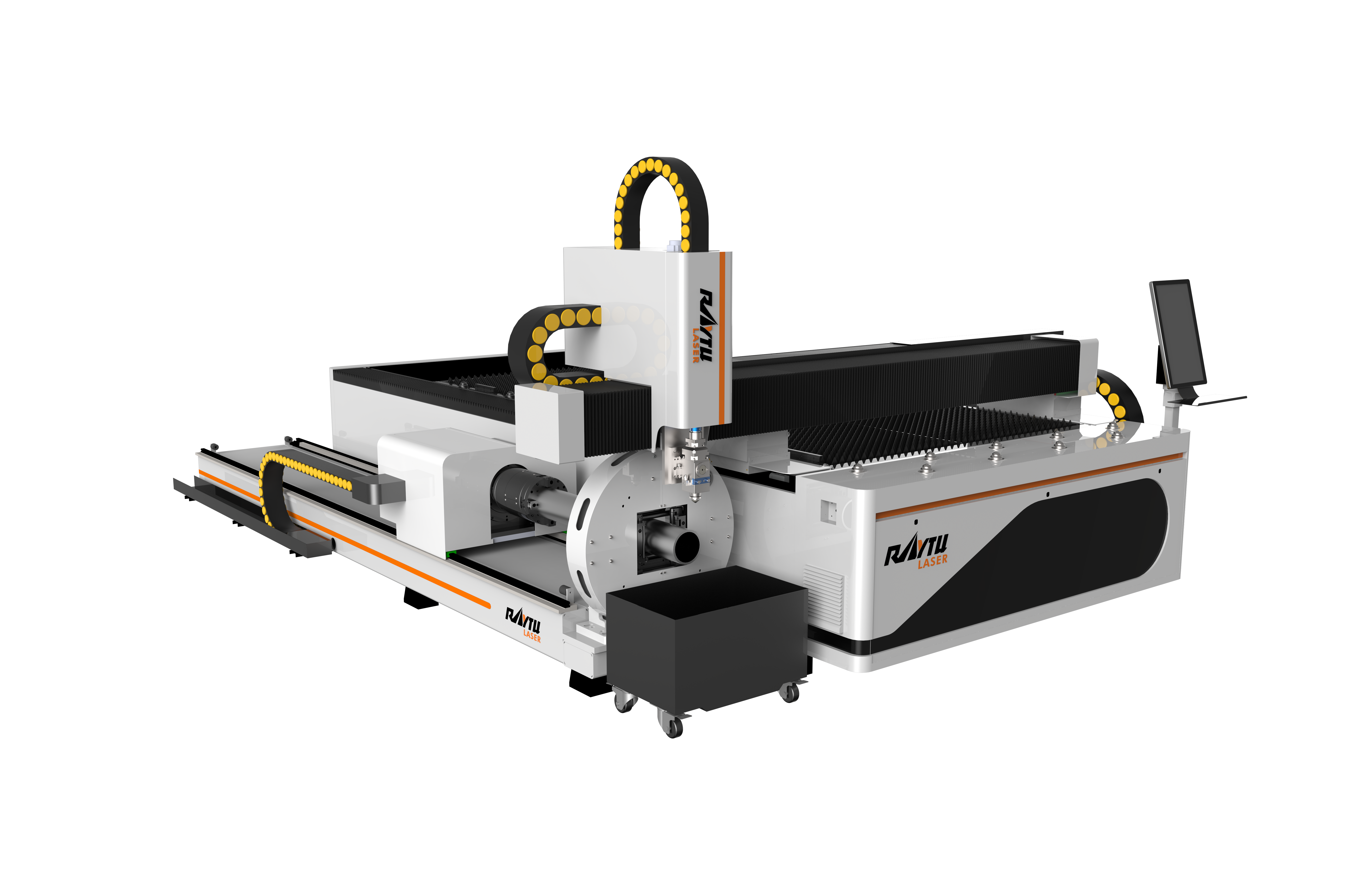

Sheet & Tube Laser Cutting Machine

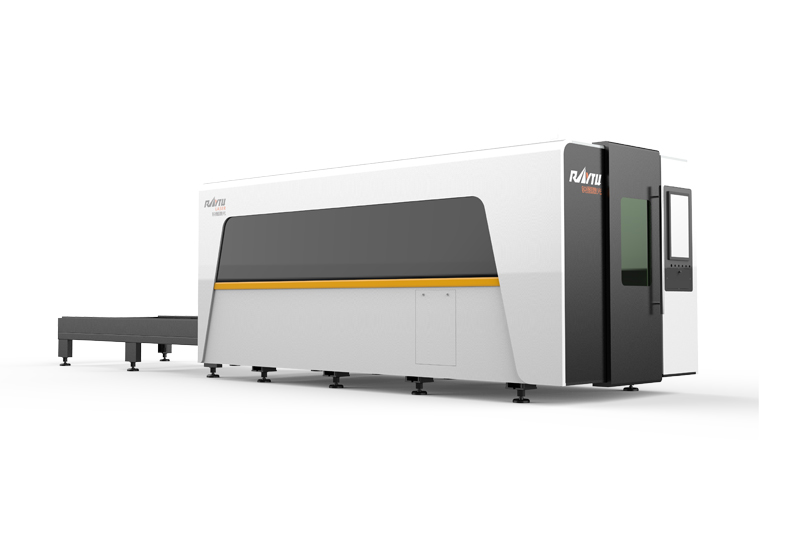

Medium Power Metal Laser Cutting Machine

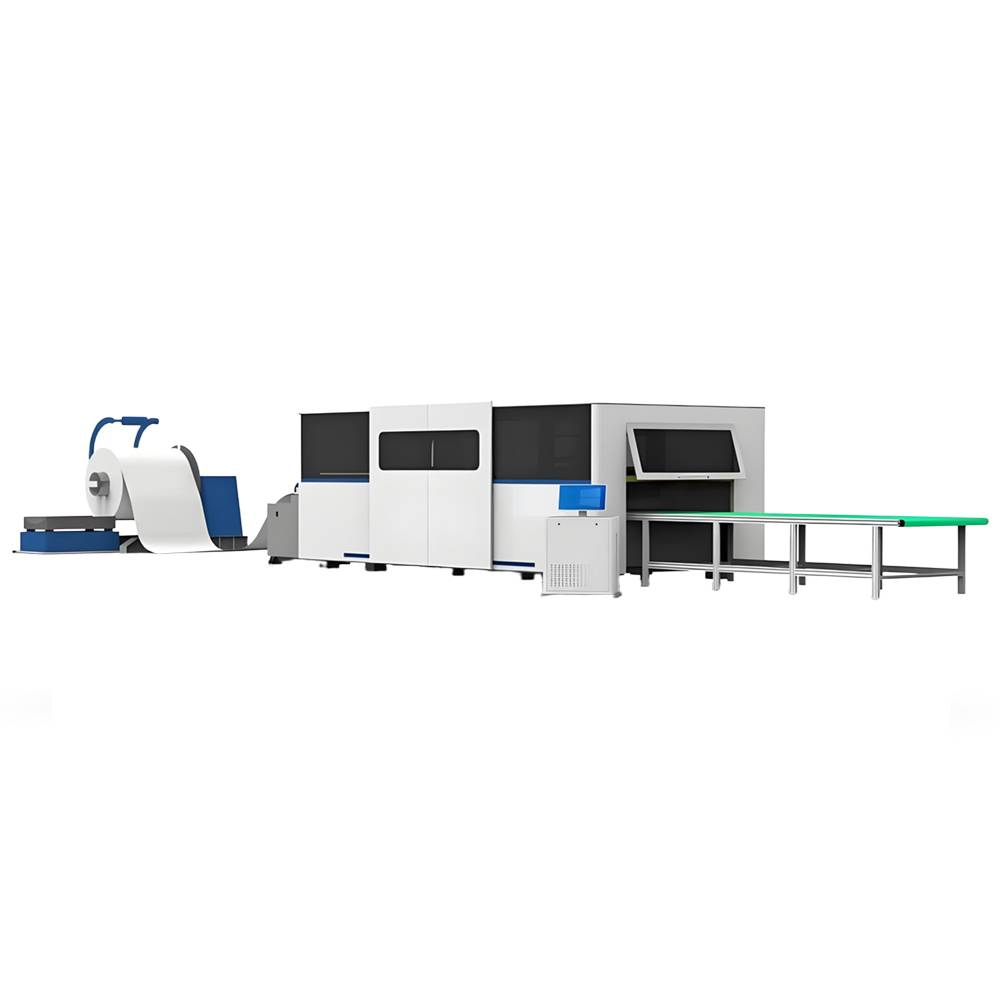

High Power Fiber Laser Cutting Machine

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us