Why Laser-Weld Stainless Steel?

Laser welding offers several advantages that make it one of the most effective methods for joining stainless steel. Its unique combination of speed, precision, and minimal thermal impact delivers results that are difficult to achieve with conventional welding methods.

Low distortion and minimal heat tint: Stainless steel is sensitive to heat, and excessive thermal input can cause warping, residual stresses, or unattractive discoloration. Laser welding’s concentrated heat source produces a narrow heat-affected zone (HAZ), which greatly reduces distortion. The controlled thermal profile also limits heat tint, preserving the metal’s corrosion resistance and reducing or eliminating post-weld cleaning.

High speed and automation-friendliness: Laser welding can be performed at high travel speeds, making it ideal for high-volume manufacturing. The process is easily integrated into automated production lines, with robotic systems delivering consistent welds without operator fatigue. This improves throughput while maintaining quality.

Excellent precision: The laser beam can be focused to a very small spot size, allowing precise weld placement. This is essential when working with thin stainless steel sections, intricate designs, or parts where tolerance for error is minimal.

Access and single-sided welding: Unlike some traditional welding methods, laser welding often requires access from only one side of the joint. This makes it valuable for complex assemblies or areas with limited accessibility.

Clean process: Laser welding is a non-contact process that produces minimal spatter, fumes, or contamination. This not only improves safety and cleanliness on the shop floor but also reduces the need for extensive post-weld finishing.

Laser welding stainless steel combines speed, precision, and minimal heat input, resulting in strong, visually clean welds with reduced rework. Its automation compatibility and single-sided access make it an ideal choice for both mass production and specialized applications, offering long-term quality and efficiency benefits.

Stainless Steel Families and What They Mean for Welding

Stainless steels are grouped into families based on their crystal structure and alloy composition. These differences directly affect their weldability, response to heat, and final mechanical properties. In laser welding, understanding these characteristics is critical to avoid defects such as cracking, distortion, loss of corrosion resistance, or phase imbalance.

Austenitic

Structure & Composition: Face-centered cubic (FCC) structure, typically containing 16–26% chromium and 6–12% nickel. Grades include 304, 316, and 310.

Weldability: Excellent weldability and ductility, but high thermal expansion can cause distortion. Low thermal conductivity can also lead to localized overheating if parameters aren’t controlled.

Laser Welding Considerations: Keep heat input low to minimize warping. Use shielding gas mixtures (e.g., argon-helium) to improve penetration and reduce oxidation. Avoid sensitization by controlling interpass temperature and cooling rate.

Applications: Food processing equipment, chemical tanks, architectural cladding.

Ferritic

Structure & Composition: Body-centered cubic (BCC) structure with 10.5–30% chromium, very little or no nickel. Common grades: 409, 430.

Weldability: Moderate weldability—prone to grain growth and embrittlement in the heat-affected zone (HAZ). Low thermal expansion means less distortion than austenitic grades.

Laser Welding Considerations: Maintain low heat input and fast cooling to avoid coarse grains. Filler metals are often unnecessary but may be used to improve toughness in thick sections.

Applications: Automotive exhaust systems, industrial appliances, decorative trim.

Martensitic

Structure & Composition: BCC/tetragonal structure with 11.5–18% chromium and higher carbon content. Common grades: 410, 420, 440C.

Weldability: More difficult to weld due to hardness and brittleness. High risk of cold cracking in the HAZ.

Laser Welding Considerations: Preheat to 150–300℃ to reduce hardness gradients. Use post-weld tempering to restore toughness. Filler materials with lower carbon content can help minimize crack sensitivity.

Applications: Turbine blades, knives, surgical instruments.

Precipitation-Hardening (PH)

Structure & Composition: Martensitic or semi-austenitic structure with additional alloying elements (e.g., Cu, Al, Nb, Ti) that allow age-hardening. Example: 17-4PH.

Weldability: Good weldability, but mechanical properties depend heavily on heat treatment.

Laser Welding Considerations: Weld in the solution-treated condition, then perform post-weld aging to regain strength. Avoid excessive heat input to prevent overaging or distortion.

Applications: Aerospace parts, high-strength shafts, petrochemical equipment.

Duplex and Super Duplex

Structure & Composition: Approximately 50/50 austenitic and ferritic phases, with high chromium (19–32%), molybdenum, and nitrogen for enhanced corrosion resistance. Common grades: 2205, 2507.

Weldability: Good weldability but sensitive to phase imbalance—too much heat can cause ferrite or sigma phase to dominate, reducing corrosion resistance and toughness.

Laser Welding Considerations: Use controlled, moderate heat input and maintain interpass temperatures below ~150℃. Shielding gas purity is critical to avoid nitrogen loss.

Applications: Offshore platforms, desalination plants, chemical processing equipment.

Every stainless steel family responds differently to the concentrated heat of laser welding. Austenitics are easy to weld but distort easily, ferritics are stable but risk grain coarsening, martensitics require preheat and tempering, PH grades need post-weld aging, and duplex types demand strict phase control. Selecting the correct laser parameters, filler metals, and post-weld treatments based on the specific family ensures welds that maintain both strength and corrosion resistance.

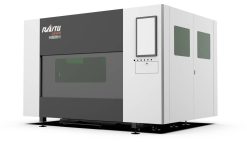

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us