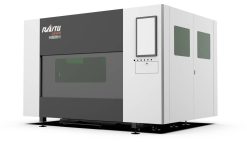

Electrical System

Check Circuit Breakers: Ensure that the main power circuit breaker and individual power supply breakers, including the emergency stop switch, respond promptly and effectively.

Verify Power Connections: Confirm that the laser machine’s power connections are correct.

Ensure Proper Capacity: Verify that the main and sub-circuit breakers (for the main unit, laser machine, air compressor, etc.) meet the specified capacity requirements.

Check Wire Gauge: Ensure that the diameter of the power, ground, and neutral wires meets the machine’s specifications and is not smaller than required.

Inspect Ground Connections: Verify that the ground connections of the power supply wires are secure and properly installed.

Examine Electrical Terminals: Check the reliability and security of all high-voltage wire terminals, especially at the input and output points of the power transformer. Ensure that all plugs and sockets are securely connected.

Monitor Voltage Stability: Regularly check the stability of the supply voltage to ensure consistent operation.

Maintain Cleanliness and Ventilation: Keep the electrical cabinet of the laser welder clean, organized, and well-ventilated.

Inspect Wiring Integrity and Safety: Regularly check all wiring for integrity and safety to prevent electrical hazards.

Optical System

Precautions

Avoid Direct Contact: Do not touch the surfaces of optical lenses (such as protective lenses and focusing lenses) directly, as this can scratch the mirror surface.

Cleaning Restrictions: Never clean optical lenses with water, detergents, or similar substances, as they can damage the special coatings on the lens surface.

Proper Storage Conditions: Do not store lenses in dark, damp places, as this can cause aging of the lens surface.

Keep Lenses Clean: Lenses must be kept clean. Dust, dirt, or moisture can absorb laser energy and damage the coatings, affecting laser beam quality or even preventing the beam from generating.

Timely Replacement: Replace lenses promptly if they are damaged.

Care During Installation: When installing or replacing protective or focusing lenses, apply minimal pressure to avoid deforming the lens, which can negatively impact beam quality.

Lens Storage

Proper Storage: Ensure that optical lenses are stored correctly to maintain their quality.

Temperature Control: Store lenses in environments with temperatures between 10–30°C. Avoid placing them in freezers or similar conditions to prevent condensation, which can damage the lenses. Temperatures above 30°C can also affect the lens coatings.

Secure Environment: Keep lenses in a box and in a stable, vibration-free environment to prevent deformation that could impair their performance.

Laser Source

Power Line Inspection: Regularly check the power lines and ensure that the laser source is grounded. Use a multimeter to verify continuity between the laser housing and the ground (PE yellow-green wire) before powering on.

Control Line Compliance: Ensure that all control lines and voltages meet the manufacturer’s technical specifications. Non-compliance can lead to irreversible damage.

Fiber Protection: Handle fiber optics with care. Avoid bending or putting stress on the fibers to prevent damage.

Lens Cleaning: Protect the optical output head from dust. If cleaning is necessary, use 99.9% pure ethanol and lint-free swabs to avoid contamination.

Monitor System Functionality: During operation, continuously check the water, gas, and electrical systems for normal functionality. If any issues arise, power off the system immediately to diagnose the problem.

Fault Documentation: If any faults occur, document the time, symptoms, and operational status of the system before troubleshooting the cause.

Cooling System Maintenance: For long-term use, regularly clean the cooling water lines and keep the laser source clean. Replace the cooling water in the chiller periodically to maintain optimal performance.

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us