Laser cutting offers a number of advantages over traditional mechanical cutting methods (such as die punching or saw cutting) as well as other similar techniques, such as plasma cutting or waterjet cutting.

Many of the advantages stem from the fact that laser cutters cut with a narrow beam with a favorable wavelength and from the fact that there is a good level of energy containment in the cutting process.

Next, we’ll share why these properties create advantages over other cutting methods.

Higher Accuracy and Smaller Kerf Sizes

Accuracy – The beam from laser machines is extremely focused and only touches a small surface area on the material, meaning that they produce very accurate and focused cuts. With accuracy levels of ±0.1 mm, laser cutters are often best where a high level of precision is required.

Kerf – The narrow area of focus with a laser beam also results in smaller kerf widths compared to other methods. Kerf is the width of the area of material removed during the cutting process.

The kerf laser cutting makes is barely larger than the size of the beam. It is possible to produce kerf widths as narrow as 0.1mm with laser cutting, although kerf widths vary between 0.1mm and 1mm. The kerf thickness depends on the laser cutter being used and the material being cut.

In comparison, waterjet cutting produces a kerf width of around 0.9mm, while oxy-fuel and plasma cutting produce kerf sizes of 1.1mm and 3.8mm, respectively. To compare laser cutting to manual cutting methods, mechanical or hand saws generally produce a kerf size of about 3.175mm (10x the kerf of a laser cutter).

Having a smaller kerf size has the following advantages:

Improved sheet utilization, which reduces waste and cost.

Reduced need to offset cutting where accuracy is important.

High Levels of Repeatability

Laser cutters produce complex, precision parts in a repeatable and efficient manner, and this allows manufacturers to create multiple exact copies of the same parts over large production runs or even in separate production runs.

Laser cutting machines are CNC controlled, and generally operated using complex software to optimize part path, machine speed and sheet metal utilization. As well as this, laser cutters also cut without making contact with the material they are cutting. No wear or degradation occurs at the laser cutters cutting edge, meaning that the cutting action does not vary across a production run. This compares to saw cutting, for example, where the blade may deteriorate or become misshaped during production.

This advantage applies when comparing laser cutting to mechanical cutting methods, such as saw cutting. Waterjet cutting and plasma cutting offer similar levels of repeatability as laser cutting.

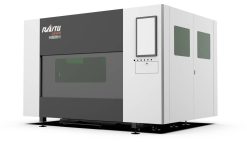

Contact us and you will get more professional details

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us